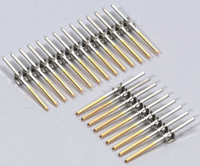

Precious Plate, in conjunction with its sister company, Precision Process Inc., has perfected a unique and efficient process for two-sided square pin plating.

Precious Plate tools reel-to-reel plating equipment in-house, specifically for each application. Return on investment (ROI) for this upfront cost is realized by significant reductions in the amount of gold, palladium, and other precious metals used during the plating process.

How two-sided square pin plating works

The two-sided square pin plating process works much like selective spot plating in that two sides of a square pin are masked and two are exposed. During the pin plating process, the exposed sides receive plating while the others do not.

The two-sided square pin plating process works much like selective spot plating in that two sides of a square pin are masked and two are exposed. During the pin plating process, the exposed sides receive plating while the others do not.

Two-sided square pin plating restricts the electrodeposit to only the sides of the pins that require plating for connectivity purposes. This electroplating technique effectively trims the number of plating surfaces in half, thus reducing precious metals used and your plating costs.

Benefits of two-sided square pin plating from Precious Plate

- Cost reducing solution for electroplating square pins

- Customized solution that meets your specific needs

- Precious Plate is an expert in the pin plating process

Metals used with the two-sided square pin plating process

Contact us to discuss your custom industrial plating project today!