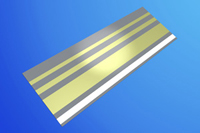

Selective stripe plating offers a cost-effective solution for selective plating of stamped parts and flat-stock material.

How selective stripe plating works

After Precious Plate designs your reel-to-reel plating process and pre-treats and undercoats your reel of stamped parts or flat stock material, selective stripe plating begins.

After Precious Plate designs your reel-to-reel plating process and pre-treats and undercoats your reel of stamped parts or flat stock material, selective stripe plating begins.

Selective stripe plating belts or wheels specific to your part will be designed in conjunction with our sister company, Precision Process Inc. The parts will be masked in all locations except the areas that require selective plating. Within the cell, stripes of gold, palladium or other metals are applied only to the exposed areas.

If selective plating of more than one type of metal is required, the selective plating process is repeated for each metal. Multiple stripes of various metals can be applied to each side of the part. This can be accomplished by a single pass through the reel to reel plating line.

Benefits of selective stripe plating

- Selective stripe plating reduces the amount of precious metal used

- Selective stripe plating is a proven, low-risk selective plating process

- Selective stripe plating provides plating deposits only in required areas with tight tolerance control

Metals used in selective stripe plating