Additive masking from Precious Plate offers ultra selective, high-speed plating of continuous coil-stock, which is ideal for applications requiring extremely tight tolerances. This patented reel-to-reel selective plating process designed and developed in conjunction with Precious Plate’s sister company Precision Process Equipment offers new opportunities for selective plating.

How Additive Masking Works

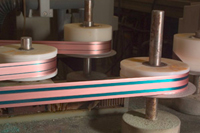

Continuous coil-stock is fed through a reel-to-reel plating line where (if required) an overall deposit of copper and/or nickel is applied. Subsequently, one or more continuous stripes of masking material are applied to the surface of the metal strip. After masking, the strip moves through a curing process rendering the maskant inert to the plating solutions and ensures that subsequent plating occurs only on the unmasked surfaces. When plating is complete, the mask is removed, exposing the undercoat of nickel. This selective plating process is capable of supplying customers with pre-plated continuous coil-stock with stripe location tolerances of +/ - .004 in (0.1 mm) at line speeds well in excess of 150 feet (45 m) per minute.

While additive masking has been used primarily with tin and tin/lead pre-plating, it has significant potential in selective plating processes where gold plating or other precious metals require plating at extremely high tolerances.

Benefits of additive masking

- Additive masking offers ultra selective plating of tin, tin/lead, and possibly other metals

- Additive masking provides high-speed plating of continuous coil-stock Metals used Tin and tin/lead plating Gold plating

Contact Precious Plate today to learn more about additive masking plating.